SAF®

FLOTATION WITHOUT

DISSOLVED AIR®

SAF® System Pilot Testing For

Water and Wastewater Applications

- 350 gpm self-priming Feed Pump with a VFD controller

- 4-inch magnetic Flow Meter

- pH control system with PID loops for acid and caustic feed

- Flow controlled outlets for coagulant feed and coagulation

- Serpentine-Style Floc Mixer

- Polymer dosing/flash mixing and aging system

- Working Tanks for conditioning chemistry

- Flotation Cell and SAF® Froth Generator

- Positive Displacement Skimmed Solids Pump

Treatability Studies

- In-house laboratory testing

- Jar tests for determining polymer and flocculent dosing rates and additions for pH control

- Analytical results developed to predict process performance and operating costs

Pilot Testing

- Pilot scale testing offered to verify process performance and operating costs derived from laboratory tests

- Trailer-mounted SAF® system equipped to handle flow rates ranging from 40 to 350 gpm with complete pH control, polymer dosing & aging, and a flotation tank offered for lease

Contained and fully integrated are:

- pH Control System with PID loops for acid and caustic feed

- controlled outlets for coagulant feed/coagulation

- polymer dosing/flash mixing/aging system supporting flocculation

- flotation separation of suspended solids and associated BOD/COD

- fully automated continuous operation including the starting/stopping system by remote signal/parameter.

Capabilities demonstrated:

- Primary influent clarification in place of primary clarifier

- Treatment of overflow pond return water containing algae/partially digested raw influent

- Clarification of activated sludge mixed liquor with concurrent thickening of MLSS.

- Digested sludge belt filter press filtrate and wash water clarification

System Capabilities and Services Provided

- Engineering design of process and components

- AutoCAD drawings for mechanical and electrical fabrication

- Provision and operation of pilot trailer

- Custom fabricated welded stainless steel tanks and components

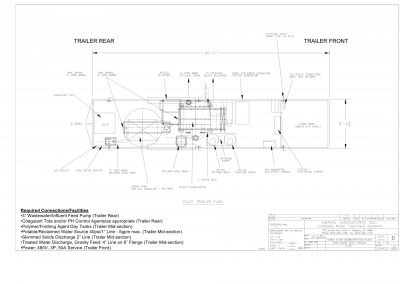

Overall Part Dimensions

Pilot trailer:

40 ft. L x 8 ft. W x 12 ft. 4 in. H

Material Used

304 stainless steel, PVC, Polyurethane

Specifications

Feed System:

7.5 HP, 250 gpm pump with 4-in. magnetic flow meter,

pH control system with acid and caustic PID Loops

Floc Mixer:

Serpentine-Style Floc Mixer, 4″ diameter, Plug flow, 100′ long, schedule 80 PVC.

Flotation Tank:

Model CF-125 ClearFloater™ Cross-Flow Flotation Cell with ClearMixer®, chain and flight skimmer, solids hopper, adjustable stainless steel weir, and observation decking.

SAF® Generator:

Model F50 (13.6 gpm froth flow rating).

Ancillary Equipment:

Polymer dilution and aging system; acid, caustic, polymer, and frothing agent metering pumps; float solids transfer pump; control panels

Results

-

SAF® demonstrates over 30 times the capacity of a conventional primary clarifier. Algae removed from pond less than 0.5 NTU. MLSS thickens using less polymer and with greater solids capture.

Industry for Use

-

Industrial & Municipal Water and Wastewater

Delivery/Turnaround Time

-

1 week