Algae Removal: Surface Water & Treatment Ponds

SAF® Systems CA Title 22 Algae Removal, Wastewater Reclamation, and Tertiary Filtration

Heron Innovators SAF® solutions are backed up by years

of process knowledge and manufacturing ability.

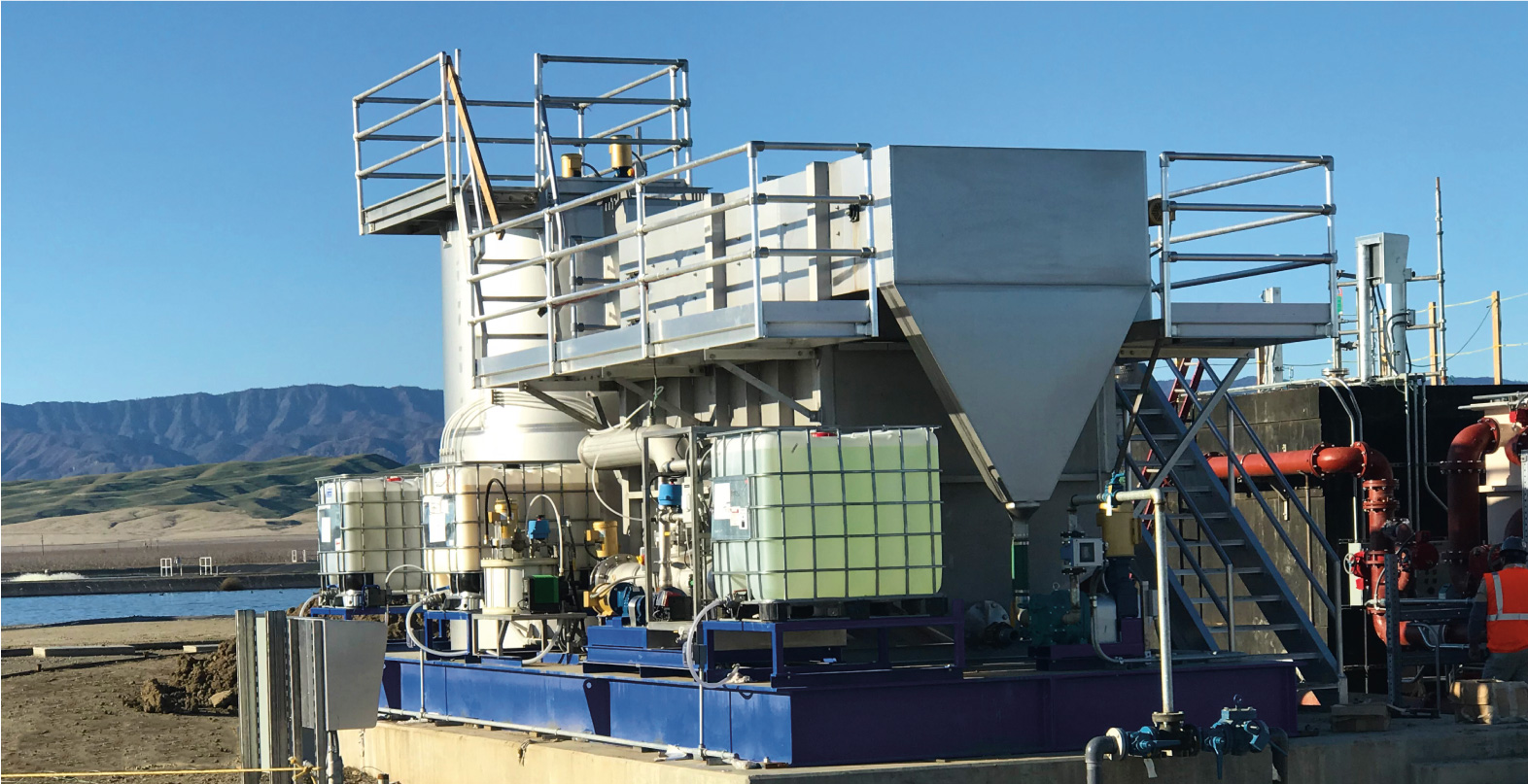

Skid-Mounted SAF® F100/CF500 Achieves < 0.5 NTUs

Removing Algae From Wastewater: Pleasant Valley State Prison, CA

SAF® F50 Achieves High Standards | Graton Community Services District, CA

This particular project required the removal of specific components – algae and colloidal material – from the pond effluent. The goal was to extend filter cycle times, and achieve <9NTU water clarity prior to filtration for unrestricted reuse of wastewater.

This particular project required the removal of specific components – algae and colloidal material – from the pond effluent. The goal was to extend filter cycle times, and achieve <9NTU water clarity prior to filtration for unrestricted reuse of wastewater.

Free Consultations

We have knowledgeable sales engineers ready to answer your project inquiries.